The Ultimate Rosemary Tincture or Tea.

When making preparation form plants one must remember that.

- Each plant is a unique individual and there is no way of knowing how much of a compound is in that plant without laboratory testing. By sourcing several, different batches of rosemary, you are more likely to even out the levels of the compounds found in the plant. You can also take steps to ensure that you select a plant likely to be high in your chosen compounds.

- The concentration of our target compounds is highly dependent on the following factors:

Where and how the plant was grown and the time of year it was harvested, then comes the drying process and finally the method of extraction. Before trying to make an extract it is important to look these factors as some plants are better than others and pre-preparation of the plant mass, if done correctly, can achieve a 6 times increase in strength and quality of Ethanol-based extracts and a 400 times increase in water-based extracts. - You may be unable to apply everything covered here, as you can only work with what you have and do your best.

|

The levels of compound contained in the plant.

This is broken down into 3 sub categories.

|

Then comes extraction and pre-treatment processes.

We can explore this in 3 more sections.

|

Growing Conditions & Enviroment

Rosemary is a Mediterranean plant that like sandy well draining soil and lots of sun.

Variations in the local environment and general growing condition have a massive effect on the content of our target compounds. Total yield of plant mass is the main consideration for the grower, choosing a plant that has a high content per gram is our requirement, unfortunately these two aspects work in opposition.

Heavy feeding and watering of the plant allows for maximum growth but the minimum % content of our target materials.

Variations in the local environment and general growing condition have a massive effect on the content of our target compounds. Total yield of plant mass is the main consideration for the grower, choosing a plant that has a high content per gram is our requirement, unfortunately these two aspects work in opposition.

Heavy feeding and watering of the plant allows for maximum growth but the minimum % content of our target materials.

- In an ideal world one would feed the plants with a high N.K.P. organic fertilizer (manure or compost) at the start of the year. Over the first few months the plants should be given plenty of water to encourage plant growth. Into that water one would add Ormus & live micro-organisms in the form of compost Tea. (This stimulates plant growth).

- Two (2) months before harvesting one should begin to restrict the water supply and add some OTE "Ocean Trace Elements". OTE causes plants to produce much more active ingredients but it lowers the growth rate.[1]

- One (1) month before harvest the plant should be given a final heavy watering and then completely starved of water until harvest. Over this month the plant should be sprayed with one of our Ormus, OTE mixes, designed to discourage the growth of white powder mildew that will otherwise spoil the harvest.

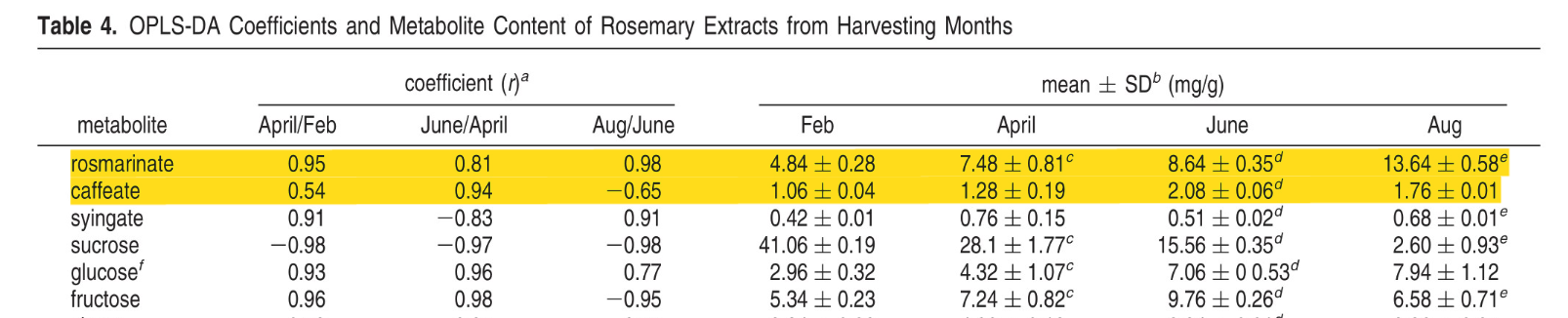

Harvest Time

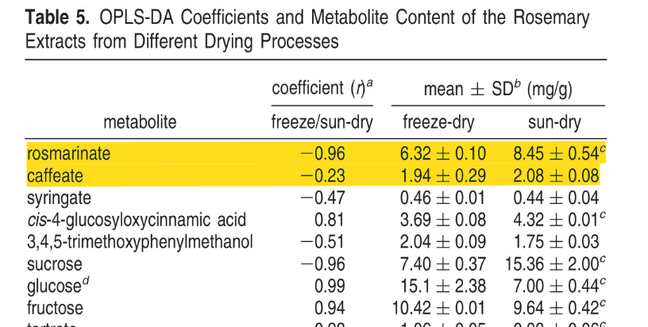

Drying Process

|

Sun drying is the preferred method.

The steady loss of water under full sun allows for cellular activity to continue as the plant dries out. While Drying the plant uses up glucose, fructose and a set of other primary metabolites trying to stay alive, this action produces more of some of our target compounds, particularly rosmaninate.[2] Rapid drying in an oven, dedicator of freeze drying does not allow for this action. |

|

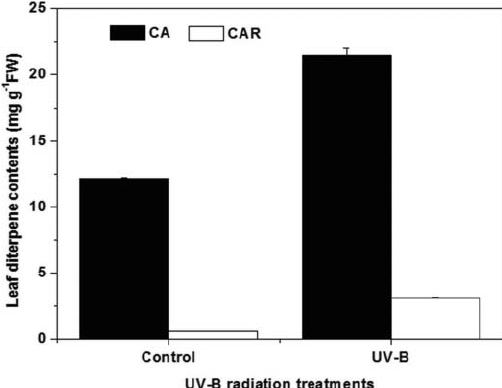

SUN OR NO SUN?

In most cases, one would dry herbs away of direct sunlight to preserve the volatile oils, but in this case the more sun the better. Exposure to UV B helps to produce more of our target compounds. [1] The ultimate process would be to use a Miron Violet Glass cover over the drying area. This filters everything except a special set of UV and IR frequencies. These frequencies enhance the quality of the plant by maintaining the Bio Photon count. It also helps to prevent moulds and bacteria growing. |

Preventing Moulds & Fungi.

Rosemary plants are often attacked by various types of while powder mildew. This is a major concern when making extracts as one must ensure that we are not contaminating the extract with poisonous or undesirable secondary compounds. Drying in full sun and especially using Miron glass can help to alleviate this problem.

When the fresh plant is collected it should be washed to remove dust and unwanted contaminants and then soaked in

Ozone Water or some other Oxygen free-radical containing material. See Hydrogen Peroxide & Chlorine Dioxide.

Rosemary plants are often attacked by various types of while powder mildew. This is a major concern when making extracts as one must ensure that we are not contaminating the extract with poisonous or undesirable secondary compounds. Drying in full sun and especially using Miron glass can help to alleviate this problem.

When the fresh plant is collected it should be washed to remove dust and unwanted contaminants and then soaked in

Ozone Water or some other Oxygen free-radical containing material. See Hydrogen Peroxide & Chlorine Dioxide.

Extraction

The Antioxidants that we are trying to extract are Rosmarinic acid and Caffeic acid.

Both are water-soluble Polphenolic acids, but successfully extracting them from the plant mass needs a little help.

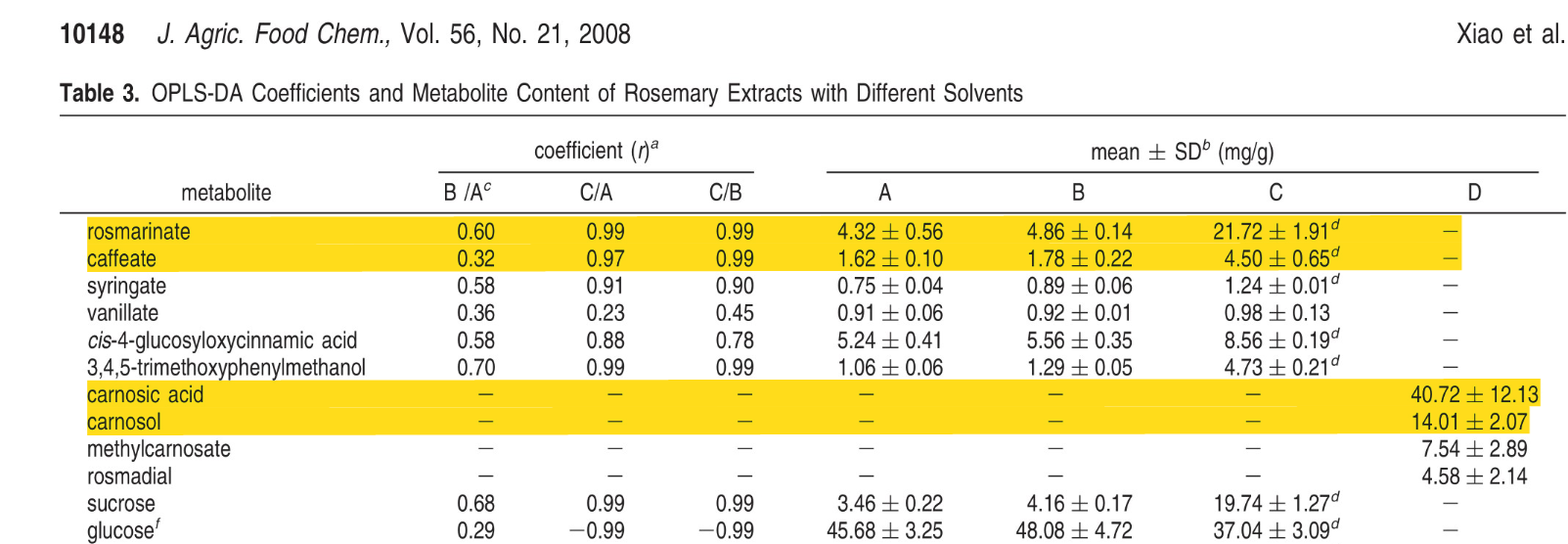

Testing across 3 different solvents with no pre treatment shows the following.[1]

Both are water-soluble Polphenolic acids, but successfully extracting them from the plant mass needs a little help.

Testing across 3 different solvents with no pre treatment shows the following.[1]

- A Water at ambient /room temperature.

- B Boiling water (Tea)

- C 1:1 Water & Methanol ([x]uses methanol but [x] used Ethanol like we will be)

As one can see from this chart we can extract the Rosmarinic acid, with the help of some alcohol, but that is problematic when you want to make an antioxidant rich tea. The other point is that one cannot extract Carnosic acid with only 50% ethanol, we will come back to it later. The first option might be to wet the leaves with a shot of vodka and allow it to digest the plant before adding the water and boiling. The other option is to pre-process or pre treat the Rosemary to make the extraction possible.

Pre Processing of Rosemary achieves amazing results.

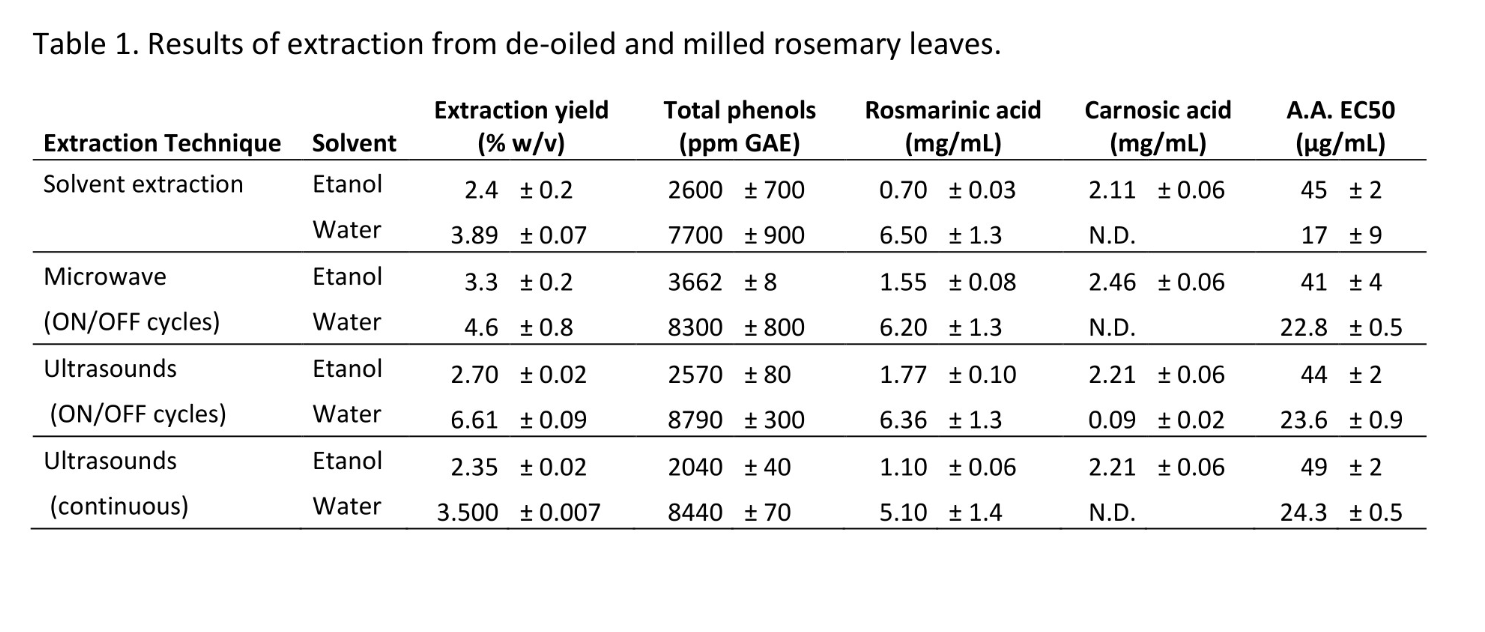

The following discussion demonstrates how it is possible pre-process the plant mass so you can run an extraction in 100% water and get 6 times the amount of extract. Ie How to make a superb tea.

Pre treatment of Rosemary Leaves [2] xxx paper

This is vital if you want to make an excellent antioxidant tea or the syrup described in the tincture production pages.

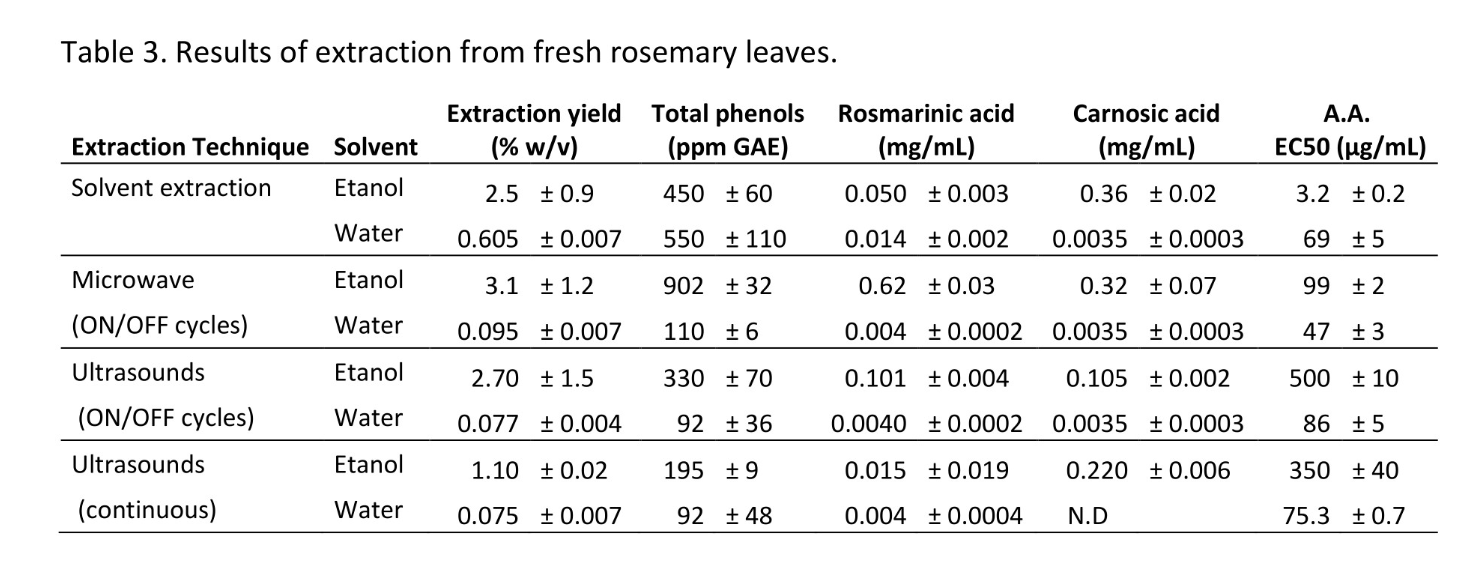

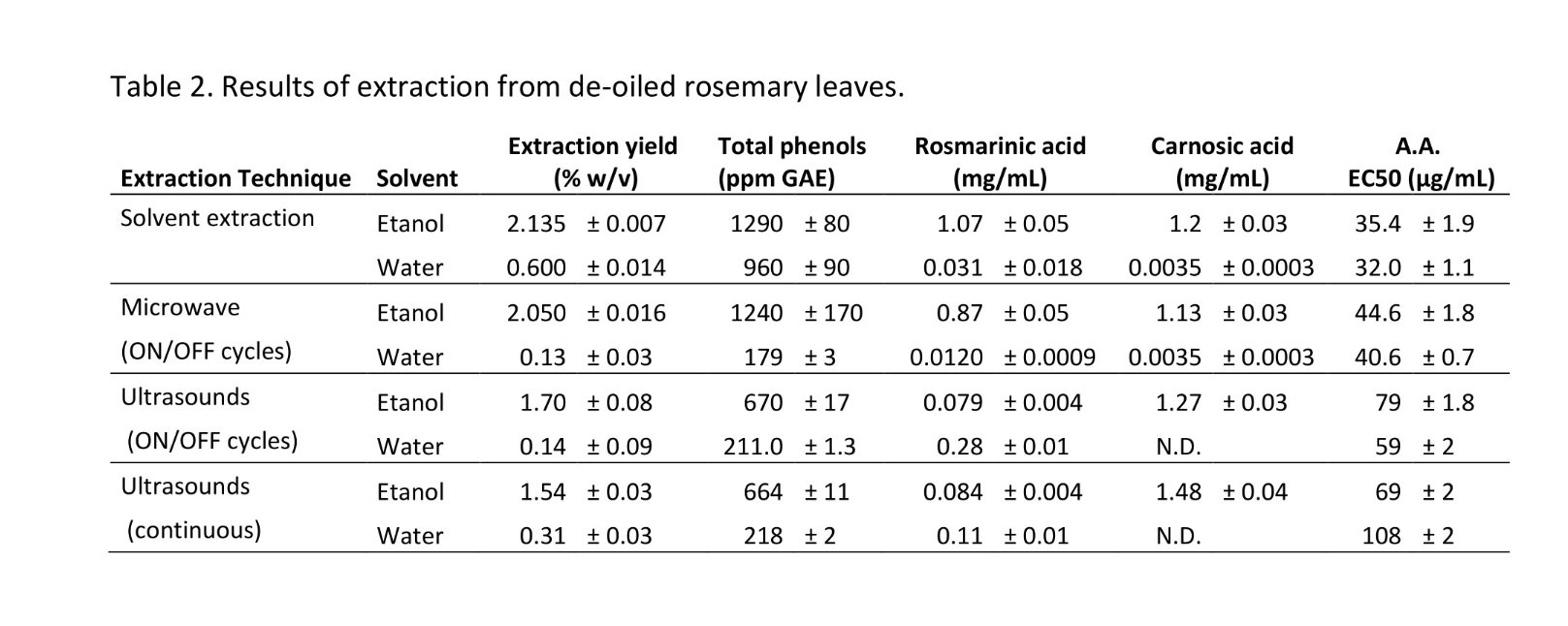

Combining the two main processes radically change the extraction profile of the antioxidants. If you are only using the plant mass for making tea, this is a real advantage. Paper [2] conducted a comparison test between plain water & 100% ethanol.

First of we can see that a 100% ethanol solvent are no good at extracting Rosmarinic acid from fresh unprocessed leaves, but it can extract the Carnosic acid.

The following discussion demonstrates how it is possible pre-process the plant mass so you can run an extraction in 100% water and get 6 times the amount of extract. Ie How to make a superb tea.

Pre treatment of Rosemary Leaves [2] xxx paper

This is vital if you want to make an excellent antioxidant tea or the syrup described in the tincture production pages.

- De-oiling by Solvent Free Microwave Extraction

The microwaving process "SFME" allows a large part of the essential oils to be released from the plant before other extractions.

This improves the xxxxx mastransfer

(dry whole leaves, heated in short 1 - 2 minute bursts at 700 - 1000W) - Grinding

Grinding the leaves into the finest of powder then changes the xxx mas transfer rate. - Ultrasound Assisted Extraction "UAE", at a steady 45- 50 C, reduces the extraction time to a few hours and draws the last of the more stubborn compounds from of the plant. This is not as important as part 1 and 2, giving a final push rather than carrying the main work-load.

Combining the two main processes radically change the extraction profile of the antioxidants. If you are only using the plant mass for making tea, this is a real advantage. Paper [2] conducted a comparison test between plain water & 100% ethanol.

First of we can see that a 100% ethanol solvent are no good at extracting Rosmarinic acid from fresh unprocessed leaves, but it can extract the Carnosic acid.

Warming the plant / alcohol mix in a microwave until it reaches 50 dec C helps, but ultrasound assisted extraction (UAE) is the way to go. Don’t put the tincture in the microwave, scientist are often rubbish cooks and tend to eat a lot of micro waved food. Many seem to have forgotten their GCSE science... If you want to warm up a sensitive liquid you do it in a water bath with an electric hot plate. (Heating Alcohol? ~ No Naked Flame!)

[4] extraction of butlinic acid shows that warming the mix is the important bit, not the microwaving during extraction.

[4] extraction of butlinic acid shows that warming the mix is the important bit, not the microwaving during extraction.

THE TIME TO MICROWAVE.

De-oiling the plant by cooking in a microwave increases the availability of both Rosmarinic and Carnosic acid extracted into pure ethanol but has little or no effect with the water based extractions.

From the study.

De-oiling / 100g of fresh plant was micro-waved for 5 min at 100 W.

Milling was carried out in a two blade coffee grinder.

The material was sized between 0.85 – 0.212mm

The plant mass was added to an extraction vessel and warmed to 40 C for 15min then the preheated solvent was added. The UAE was carried out at 40deg C for only 7 min but it had not saturated

They were using a 400w / 22mm horn running at 24Khz..

We only have a twin set of 60 in a 3 lt tank.

1:4 w/volume...25g in 100ml.Or 25g in 100g = 125 ml

5ml ethanol with 3mil of glycerine with 1 drop of concentrate per ml.)

De-oiling the plant by cooking in a microwave increases the availability of both Rosmarinic and Carnosic acid extracted into pure ethanol but has little or no effect with the water based extractions.

From the study.

De-oiling / 100g of fresh plant was micro-waved for 5 min at 100 W.

Milling was carried out in a two blade coffee grinder.

The material was sized between 0.85 – 0.212mm

The plant mass was added to an extraction vessel and warmed to 40 C for 15min then the preheated solvent was added. The UAE was carried out at 40deg C for only 7 min but it had not saturated

They were using a 400w / 22mm horn running at 24Khz..

We only have a twin set of 60 in a 3 lt tank.

- Sample size 25 g

- Plant to solvent ratio 1:6 w/w 25g to 150g = 190ml Ethanol.

- The first test batch we ran was 25 g with 500ml of ethanol, is this too thin?

1:4 w/volume...25g in 100ml.Or 25g in 100g = 125 ml

- As we are expecting a 6 times increase in alcohol based extraction over a normal extraction we can try to balance the plant to Ethanol ratio a little so our end product is not to strong.

- Running 25 in 200 ml sounds good or we could work in 25g to 300ml.

5ml ethanol with 3mil of glycerine with 1 drop of concentrate per ml.)

Rosemary TEA.

Rosemary Tea | Simple & Highly Effective.

Refferences

[1]Enhanced Phenolic Diterpenes Antioxidant Levels Through Non-transgenic Approaches

November 2012 Critical Reviews in Plant Sciences 31(6)DOI: 10.1080/07352689.2012.696457

Project: Study in the possible use of saline water to irrigate aromatics plants of commercial interest: Effects of salinity on growth, essential oils and phenolic diterpenes composition in rosemary and sage.

[2] Journal of Agricultural & Food Chemistry J.Agric. Food Chem. 2008, 56, 10142-10153

Revealing the Metabonomic Variation of Rosemary Extracts using 1H NMR Spectroscopy and multivariate Date Analysis

Sate Key Laboratory of magnetic resonance – Whuan Centre of Magnetic Resonance

November 2012 Critical Reviews in Plant Sciences 31(6)DOI: 10.1080/07352689.2012.696457

Project: Study in the possible use of saline water to irrigate aromatics plants of commercial interest: Effects of salinity on growth, essential oils and phenolic diterpenes composition in rosemary and sage.

[2] Journal of Agricultural & Food Chemistry J.Agric. Food Chem. 2008, 56, 10142-10153

Revealing the Metabonomic Variation of Rosemary Extracts using 1H NMR Spectroscopy and multivariate Date Analysis

Sate Key Laboratory of magnetic resonance – Whuan Centre of Magnetic Resonance